Toyota Production System and Lean Fundamentals

Why take this course?

🎓 Master the Art of Efficiency with "Toyota Production System and Lean Fundamentals" 🚀 **Course Instructor: Ahmed Radwan 🏫

Headline: Test Your Knowledge & Learn the Foundational Principles, Pillars, and Key Concepts of the Toyota Production System!

Course Overview:

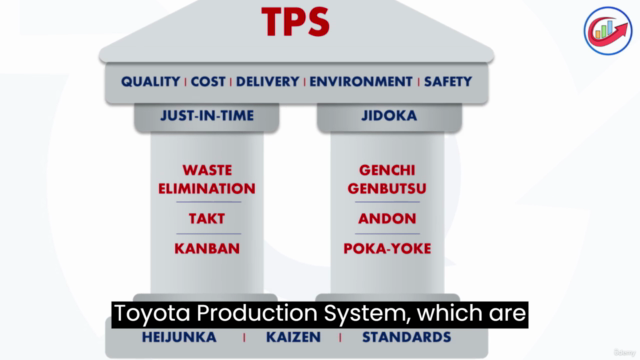

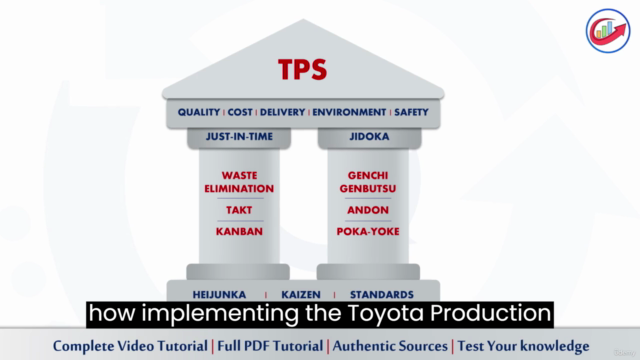

Welcome to a transformative journey into the world of Lean manufacturing with our comprehensive online course. The Toyota Production System (TPS) is not just a method; it's a philosophy that has revolutionized manufacturing processes globally. This course will unveil the secrets behind TPS and its consistent success in various industries. You'll learn why competitors continue to strive for its benchmark without ever truly replicating it, thanks to its scientific approach and commitment to continuous improvement.

What You Will Learn:

- 🔍 Understand the Core Values & Principles: Gain a deep understanding of TPS's guiding principles, including the importance of respect for people, continuous improvement (Kaizen), and standardization of work processes.

- 🛠️ Explore Key Concepts: Dive into the fundamental concepts such as Heijunka (level scheduling), JIDOKA (autonomation with a human touch), Just-In-Time inventory management, and Waste Elimination strategies.

- 🧐 Implement TPS Tools & Techniques: Learn how to apply tools like Standards, Genchi Genbutsu (go and see), Andon (visual signaling system), Poka Yoke (failure proofing), and Kanban (just-in-time inventory control).

- 🏆 Tact Time & Waste Elimination: Master the concepts of Takt Time and learn how to use it effectively to optimize production flow. Understand the seven types of waste in Lean and how to eliminate them.

Course Structure:

-

Module 1: Introduction to Lean & TPS

- The history and evolution of TPS.

- Key differences between Lean and Six Sigma.

-

Module 2: Foundational Principles of TPS

- The three "M"s: Manage, Make, Maintain (Manufacturing, Machines, and Maintenance).

- Respect for People & Team Work.

-

Module 3: Pillars of TPS

- JIDOKA & Autonomation Philosophy.

- Just-In-Time Inventory Management.

-

Module 4: Key Tools & Techniques

- Heijunka & Scheduling.

- Kaizen & Continuous Improvement Processes.

- Standards, Genchi Genbutsu, Andon, Poka Yoke, Kanban in Practice.

-

Module 5: Waste Elimination

- Identifying and eliminating waste.

- Creating flow and value in the production process.

Course Benefits:

- Expert Guidance: Learn from Ahmed Radwan, an experienced MBA with a rich background in Continuous Improvement and Lean/Six Sigma.

- Real-World Applications: Apply TPS principles to your own work environment for immediate impact.

- Interactive Learning: Engage with quizzes and practical exercises to test your knowledge and solidify your understanding of TPS concepts.

Course Outcome:

Upon successful completion of the course, you will earn the prestigious "Master Lean Manufacturing: The Toyota System Unleashed." Certificate, signifying your mastery of TPS principles and your ability to apply them effectively in any production environment.

Embark on Your Continuous Improvement Journey:

This course is designed to empower you with the knowledge and tools necessary to implement TPS and reap its countless benefits. Whether you're a seasoned professional or just starting out, this course will challenge you to think differently and excel in your pursuit of operational excellence.

🎓 Enroll Today and Step into a World of Operational Mastery with "Toyota Production System and Lean Fundamentals"! 🚀

Course Gallery

Loading charts...