P Chart & Laney P' Chart Analysis in Minitab – Tabtrainer®

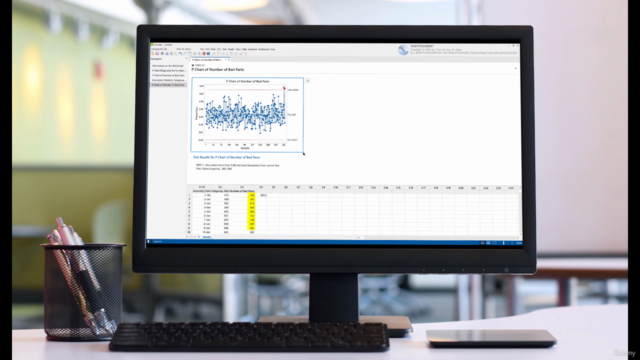

Master control chart analysis for attribute data in Minitab – detect process instability with real-world factory example

0

students

35 mins

content

May 2025

last update

$19.99

regular price

What you will learn

Identify nominally scaled attribute data and apply the principles of binomial distribution to evaluate production quality using real data.

Differentiate between relative defect rates in P Charts and absolute defect counts in NP Charts, understanding when to use each method.

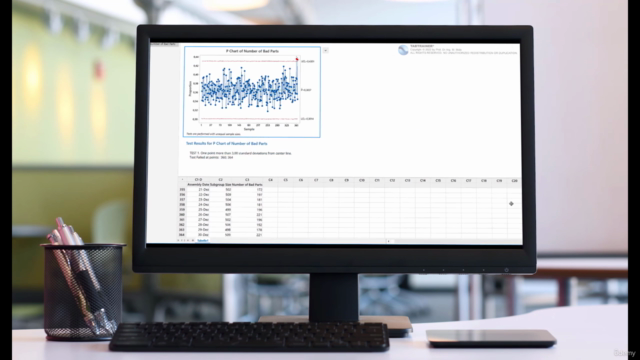

Analyze control chart signals and trace root causes of process instabilities, using real examples like increased defects during holidays.

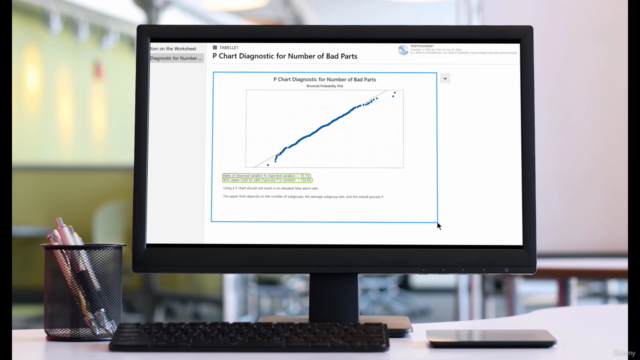

Interpret probability plots from the P Chart Diagnostic to validate if process data meet binomial assumptions and decide on the correct control chart.

Perform a full P Chart Diagnostic to determine if the data's dispersion matches the expected random behavior of a binomial distribution.

Apply AIAG guidelines to smooth control limits by assessing whether subgroup size variations meet the standard’s 75% tolerance condition.

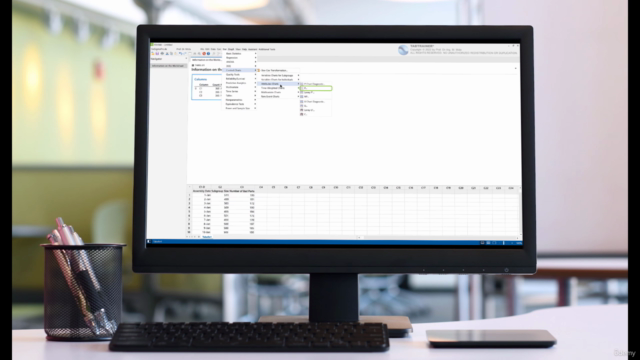

Import and explore real-world production data with 365 records, analyzing assembly dates, subgroup sizes, and number of defective skateboards.

Calculate daily defect rates by relating the number of bad skateboards to the total produced, adapting to fluctuating daily subgroup sizes.

Save the entire defect rate analysis project, ensuring structured documentation and easy reference for future process improvements.

Course Gallery

Loading charts...

6587859

udemy ID

28/04/2025

course created date

02/05/2025

course indexed date

adedayo0001

course submited by