Process Capability Analysis in Minitab – Tabtrainer®

Master Cp, Cpk, Pp, Ppk & Cpm in Minitab – apply AIAG rules, evaluate stability, reduce scrap, drive performance

5.00 (1 reviews)

2

students

1.5 hours

content

May 2025

last update

$29.99

regular price

What you will learn

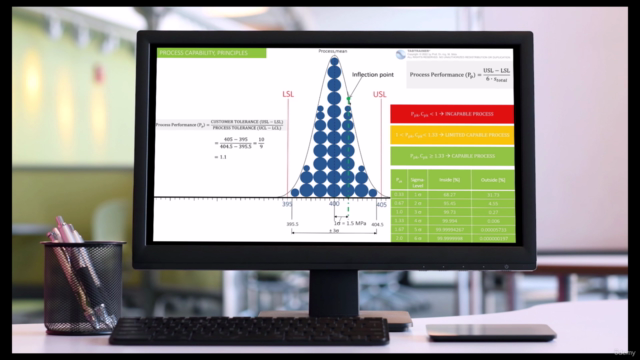

Explain the concept of process capability and distinguish between overall and potential capability.

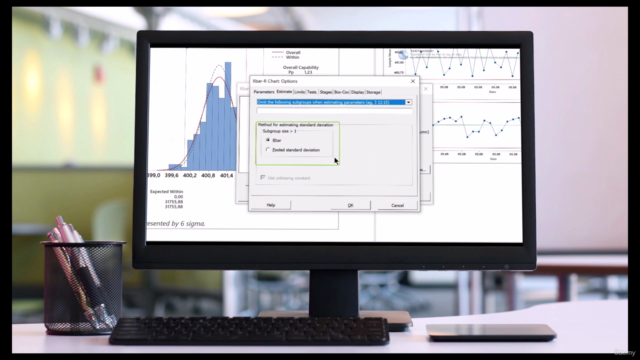

Perform a complete process capability analysis for continuous, normally distributed data using Minitab®.

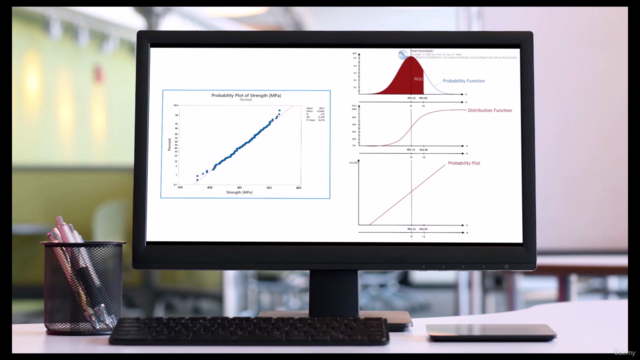

Verify normality assumptions using the Anderson-Darling test and interpret p-values correctly.

Construct and interpret X-bar and R control charts to assess process stability.

Differentiate between standard deviation within and standard deviation overall, and understand their implications for capability.

Calculate and interpret key capability indices including Cp, Cpk, Pp, Ppk, and Cpm.

Assess the centering and variation of a process using visual tools such as histograms, probability plots, and dot plots.

Identify and analyze causes of process shift and variation using practical tools like root cause analysis and supplier-based grouping.

Apply improvement measures and validate their effectiveness through comparative capability analysis.

Communicate capability results effectively to stakeholders and support continuous quality improvement initiatives.

Course Gallery

Loading charts...

6578879

udemy ID

20/04/2025

course created date

02/05/2025

course indexed date

adedayo0001

course submited by