Six Sigma: Lean Six Sigma Black Belt (Part 2) (Accredited)

Why take this course?

Based on the information provided, here is a structured outline of what you can expect in the Six Sigma Lean Black Belt (Part 3) course, focusing on Phases 2 and 3 of the Black Belt program:

Phase 2 - Measure

-

Introduction to Measure: Overview of the Measure phase, its importance in DMAIC (Define, Measure, Analyze, Improve, Control), and how it fits into the overall project process.

-

Cost of Poor Quality (COPQ): Methods to calculate and analyze the costs associated with poor quality within a process, including prevention costs, appraisal costs, internal failure costs, and external failure costs.

-

Process Map: Techniques for mapping out processes to understand workflow and identify areas for improvement.

-

The 8 Wastes: Identification of the eight types of waste in a process that can lead to inefficiency, such as defects, overproduction, waiting, non-used talent, transportation, inventory, motion, and extra-processing.

-

Value Stream Map (VSM): A detailed analysis of the value stream of products or services for the purpose of optimizing operations.

-

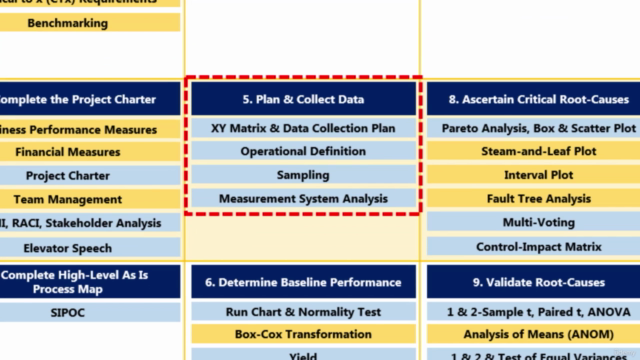

XY Matrix: A tool for understanding how different process inputs can affect outputs and for identifying which factors have the most impact on your process's performance.

-

Data Collection Plan: Strategies for systematically collecting quality data to measure a process's performance and to determine the nature of the variation in the process.

-

Operational Definition: Creating clear, specific definitions of terms used within a project so that everyone involved has the same understanding.

-

Sampling: Techniques for selecting samples from a larger population to make accurate assessments about the entire population without examining every individual element.

-

Measurement System Analysis (MSA): Evaluating the measurement system to ensure that it is capable of producing reliable data, focusing on errors and biases in the system.

-

Run Chart: A tool for monitoring a process over time to identify patterns or trends that can indicate stability or instability in the process.

-

Normality Test: Statistical tests used to determine if a set of data follows a normal distribution, which is critical for certain advanced statistical methods.

-

Box-Cox Transformation: A technique used to stabilize variances and transform data to achieve normality before applying advanced statistical techniques.

-

Yield: Calculating the yield of a process, which is the percentage of items that meet specifications after processing.

-

Process Capability - Discrete: Assessing the capability of a process with discrete data (counts or number of defectives) to meet customer requirements and expectations.

-

Process Capability - Continuous: Evaluating the capability of a continuous process to meet specific performance targets over time.

Phase 3 - Analyze

-

Introduction to Analyze: Understanding the purpose and importance of the Analyze phase in identifying root causes, underlying issues, and key factors that influence a process's performance.

-

Brainstorming: A technique for generating a list of potential solutions or root causes by systematically encouraging creativity from all participants.

-

Fishbone Diagram (Ishikawa): A cause-and-effect diagram used to systematically identify and categorize the potential causes of a problem or a quality characteristic.

-

5 Whys Analysis: A technique to explore the root cause(s) of a problem by asking "Why?" five times, or as many times as necessary, alongside the corresponding "How?" to suggest potential solutions.

-

Pareto Analysis: Using the 80/20 rule to identify and prioritize the most significant factors that contribute to a problem or its solution.

-

Statistical Tools for Analyze: Introduction to various statistical tools, such as histograms, scatter diagrams, control charts, and process capability analysis, to analyze data and identify patterns or trends.

-

Root Cause Analysis: Techniques to drill down into the underlying reasons for problems, defects, or issues in a process to ensure that corrective actions address the true cause of concern.

-

Experimental Design: Planning experiments to test hypotheses about a process and to optimize it by determining the most significant factors affecting its performance.

-

Regression Analysis: Using statistical methods to examine relationships between variables, allowing for a deeper understanding of how changes in one variable might predict changes in another. Supplementary Materials:

- A set of 30 practice questions for Phase 2 and 3 to test your understanding and preparation for the Black Belt exam.

- Downloadable slides for Phase 2 and 3, which can be used as a reference or presentation aid.

This course is designed to equip you with the knowledge and skills necessary to become a certified Six Sigma Black Belt and to apply these methodologies effectively in improving business processes. It is important to note that the actual certification process typically involves a combination of training, passing an exam, and applying the principles in real-world scenarios.

Course Gallery

Loading charts...