Quality Process Audit & control for PCBA Wave Solder & Test

Why take this course?

Course Headline: Master the Art of Quality Process Audit & Control for PCBA Wave Solder & Test 🚀

Course Description by Evelyn - Your Expert Instructor at 7E Academy:

👩🏫 Introduction to PCBA Wave Soldering and Testing: Wave soldering is a critical process in the manufacturing of Printed Circuit Boards (PCBAs), where components are secured onto the board with solder. This method is essential for both through-hole and surface-mount technology (SMT) components, ensuring they are well-attached for functionality and durability. The wave soldering process begins with meticulous component preparation, followed by careful insertion into the PCBA, and culminates in a dip into a solder wave. Given the large batches typically processed, even a minor error can lead to an entire batch of defective products, necessitating costly rework or disposal.

👉 The Importance of Process Control: In the high-stakes environment of PCBA manufacturing, maintaining strict process control is paramount. A single oversight can compromise an entire production line. That's why a robust and efficient quality audit and control system are indispensable for consistent product excellence.

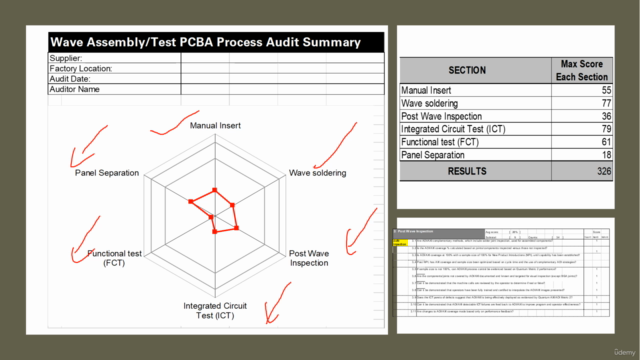

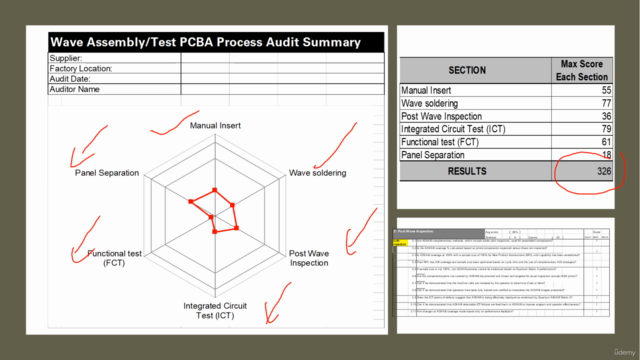

📝 Comprehensive Quality Audit Checklist: Drawing from over a decade of experience in auditing and collaborating with more than 100 PCBA manufacturers globally, I have developed an extensive quality audit checklist. This checklist encompasses over 300 control points meticulously crafted to ensure the highest standards of quality for wave soldering and testing processes.

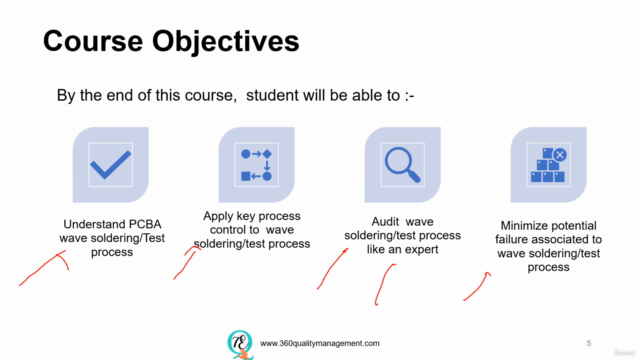

🔍 Learning Objectives:

- Understand the intricacies of the PCBA wave solder & test process.

- Gain insights into setting up a controlled and monitored process for optimal quality output.

- Learn from a pool of subject matter expert knowledge in PCBA process control and quality audit.

- Utilize my comprehensive checklist to conduct thorough audits on your PCBA manufacturing line.

🎓 Course Content Breakdown:

- A detailed exploration of the wave solder process, from component preparation to final product inspection.

- Guidance on setting up and maintaining effective inspection and test processes, including In-Circuit Testing (ICT) and Functional Testing (FCT).

- Strategies for identifying potential defects and implementing corrective actions.

- Step-by-step instructions on monitoring and controlling the PCBA wave solder & test process to achieve consistent quality.

🌟 Why This Course? In today's competitive market, producing high-quality PCBAs is not just a preference but a necessity. This course equips you with the knowledge and tools to ensure that every PCBA that leaves your facility meets the highest standards of excellence. By applying the techniques learned here, you will contribute significantly to your company's reputation for quality and reliability.

📆 Key Takeaways:

- A deep understanding of the wave solder & test process in PCBA manufacturing.

- Practical experience with a comprehensive quality audit checklist.

- The ability to control and monitor processes effectively to minimize defects.

- Confidence in applying these techniques to produce consistently high-quality PCBAs.

Ready to elevate your PCBA production line to world-class standards? Enroll now and embark on a journey to quality excellence with Evelyn's Quality Process Audit & Control for PCBA Wave Solder & Test course at 7E Academy! 🎓✨

Course Gallery

Loading charts...