Process Capability Analysis | For Engineers

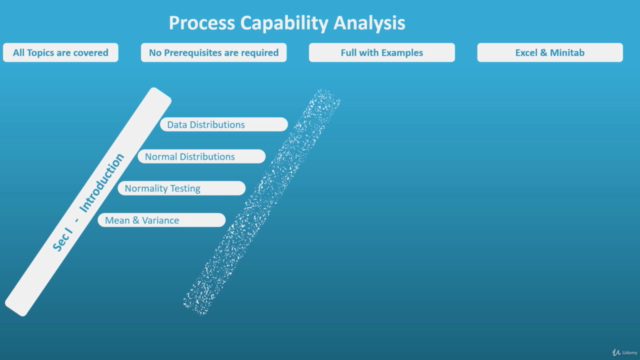

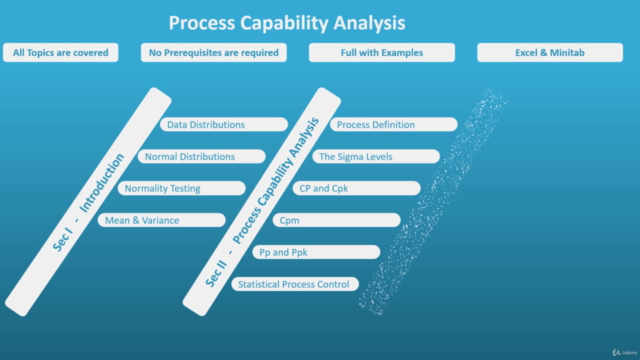

Why take this course?

Process capability, often denoted as CP (Capability Index), and Process Potential, denoted as PPK (Process Potential Index), are key concepts in quality control and Six Sigma methodologies. They both measure how well a process performs relative to the specifications of the product or service it produces. Here's a brief overview of these concepts and their relationship:

Process Capability (CP):

- CP is a measure of a process's ability to produce products within specification limits based on historical data.

- It answers the question, "How well has this process performed in the past?"

- The CP is calculated using control chart data and compares the actual performance of the process (X-bar and R or sigma) to the process specification limits (USL and LSL).

- CP is typically expressed as a ratio between the natural process spread (6σ range) and the specification width (USL - Cp) or (LSL + Cp), where Cp is the capability index.

- A CP of 1 indicates that the process mean and spec limits are coincident, meaning that 100% of products produced by the process would be within specification.

Process Potential (PPK):

- PPK represents the ideal performance of a process, assuming it operates at its theoretical best without any systematic bias or shift from target (or true mean).

- It answers the question, "How well could this process potentially perform if it were perfect?"

- PPK is calculated using the process's inherent variability (natural process spread) and assumes a perfectly centered process.

- PPK is also a ratio between the natural process spread and the specification width, similar to CP, but without any allowance for centering bias.

- A PPK of 1 indicates that every part produced by the process would be within the specification limits, assuming no shift from target.

Capability Analysis:

- Capability analysis involves determining both CP and PPK to understand not only how well a process performs historically (CP) but also how well it could perform theoretically if it were perfectly centered (PPK).

- Minitab, a statistical software package, can be used to calculate CP and PPK along with Cpk, which combines both centering and consistency into one measure.

Capability Index (Cpk):

- Cpk is a single metric that incorporates both the capability of the process (CP) and how well the process is centered around the target value (PPK).

- It is calculated as the minimum of CP and PPK, which means it will be limited by whichever is smaller.

- A Cpk value of 1.33 or higher is often considered indicative of a Six Sigma process, although this threshold can vary depending on the specific requirements of an industry or organization.

Calculation Formulas:

- CP = (USL - LSL) / (6σ_process)

- PPK = (USL - LSL) / (6σ_theoretical)

- Cpk = min(CP, PPK)

Where:

- USL is the Upper Specification Limit

- LSL is the Lower Specification Limit

- σ_process is the standard deviation of the process (often denoted as sigma in Six Sigma terminology)

- σ_theoretical is the inherent variability of the process, assuming it is perfectly centered (which may be estimated from historical data if the process is not perfectly centered)

Example: Assume a process has a range between USL = 100 and LSL = 85. If the standard deviation of the process is sigma = 2.57 (or about 3.455 for sigma conversion), then the CP would be calculated as follows:

CP = (USL - LSL) / (6 * sigma) = (100 - 85) / (6 * 2.57) ≈ 0.97

If the process is perfectly centered with no bias from the target, the PPK would be calculated as follows:

PPK = (USL - LSL) / (6 * theorical_sigma) where theoretical_sigma could be estimated from historical data. Assume it's also 2.57, then:

PPK = (100 - 85) / (6 * 2.57) ≈ 1.45

The Cpk would then be the minimum of CP and PPK, which in this case is CP = 0.97.

In practice, capability analysis is a critical tool for continuous improvement efforts like Six Sigma, as it helps identify areas where a process can be improved to meet or exceed customer requirements and expectations.

Course Gallery

Loading charts...