Operations Management. Strategy, Process design and supply.

Why take this course?

Operations Management encompasses a broad range of processes within an organization, including job design, capacity planning, inventory management, supply chain management, and the implementation of systems like Enterprise Resource Planning (ERP). Each of these areas plays a crucial role in ensuring that an organization can deliver products or services efficiently and effectively. Let's break down how you might approach each of these areas step by step.

-

Job Design:

- Human Resource Management: Understand the roles and tasks within a job, and design them to optimize employee performance and satisfaction.

- Allocation of Tasks: Assign tasks based on employee skills, motivation, and organizational needs.

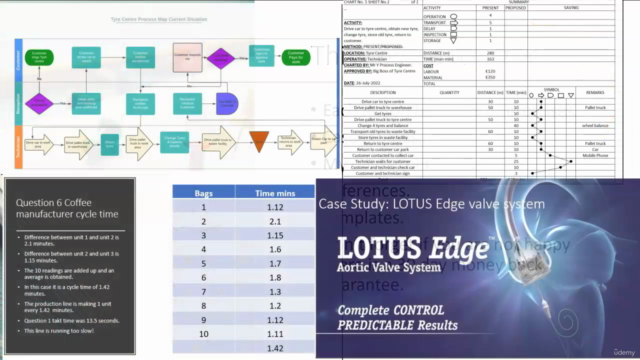

- Work Measurement: Use methods like Work Sampling or Time Study to measure how long tasks take to allocate resources effectively and improve efficiency.

- Designing the Working Environment: Consider ergonomics and the impact of the work environment on job performance.

- Motivation Theory: Apply theories of motivation to design jobs that encourage productivity and engagement.

- Behavioral Approach to Job Design: Use insights from psychology to design jobs that fit the employees' behaviors and capabilities.

-

Method Study:

- Time Study: Learn how to observe and measure how a job is done to identify ways to improve efficiency.

-

Capacity Planning:

- Understanding Capacity: Determine the maximum amount of work an operation can handle under existing conditions.

- Short, Medium, and Long-Term Planning: Plan for different time frames to ensure operations can meet demand.

- Making a Capacity Plan: Assess current capacity against forecasted demand and adjust as necessary.

- Impact of Demand: Understand how changes in demand can affect capacity requirements.

-

Managing Inventory:

- Understanding Inventory: Learn what inventory is and why it's essential for operations.

- Managing Demand: Use level capacity or chase demand strategies to manage inventory levels.

- Economic Order Quantity (EOQ): Calculate the optimal order quantity to minimize total inventory costs.

- Inventory Costs: Consider the costs of ordering, storing, and holding inventory.

- Bin System: Organize storage areas to reduce picking times and minimize travel distances.

- ABC Analysis: Prioritize inventory based on importance, using an ABC classification system.

- Other Considerations: Factor in lead times, supplier performance, and obsolescence risks.

-

Supply Chain Management:

- Understanding the Supply Chain: Recognize the flow of goods and services from raw materials to end consumers.

- Activities of SCM: Identify the various activities involved in supply chain management, including sourcing, production, logistics, and distribution.

- Choosing a Supplier: Evaluate potential suppliers using a weighted scoring model based on criteria like cost, quality, delivery time, and reliability.

-

Enterprise Resource Planning (ERP):

- Understanding ERP: Learn how an ERP system integrates various functions across an organization to streamline processes.

- Material Requirements Planning (MRP): Understand how MRP systems plan material requirements based on the master production schedule.

- Bill of Materials (BOM): Use BOM to specify the raw materials and components needed to manufacture a product.

- Inventory Status: Monitor inventory levels and forecast future requirements.

- MRP Report: Analyze MRP reports to make informed decisions about production schedules, material procurement, and inventory management.

Throughout these processes, it's important to use data analytics and continuous improvement methodologies to refine operations. By integrating these processes within an ERP system, organizations can achieve a high level of coordination and efficiency, leading to improved customer satisfaction and financial performance. Each step should be evaluated regularly for effectiveness and adjusted as necessary to adapt to changes in the market or within the organization.

Course Gallery

Loading charts...