Mastering Electrical Transformer Fundamentals Part 3

Why take this course?

Thank you for providing a comprehensive list of topics related to power and distribution transformers. The topics you've listed cover a wide range of areas, including design considerations, performance characteristics, protection systems, maintenance, testing, and troubleshooting. Here's a brief overview of how these topics are typically addressed in the field of electrical engineering:

-

Forage Transformer or Potential Transformer: These transformers step up or step down voltage for protection and measurement purposes.

-

46 Zig Zag Transformer: This is a type of autotransformer used to regulate voltages without changing the frequency.

-

47 Types of Transformers: Includes power, instrument, isolation, and special-purpose transformers.

-

48 Transformer Design Considerations: Cores (lamination, core type), windings (insulation, number of turns), coolants (air, oil), and shielding (to prevent electromagnetic interference).

-

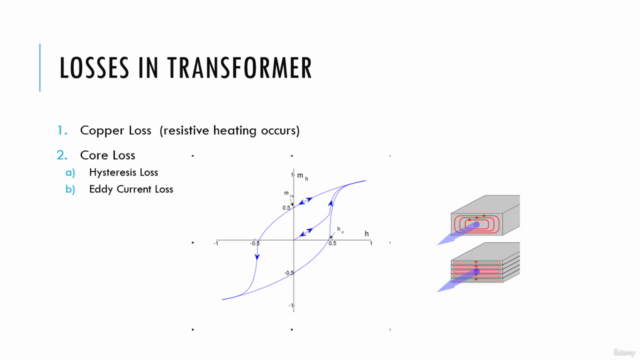

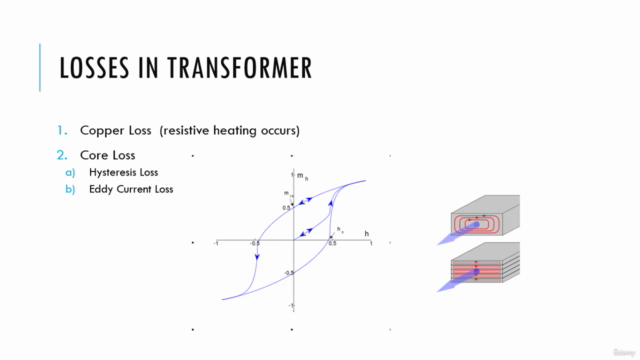

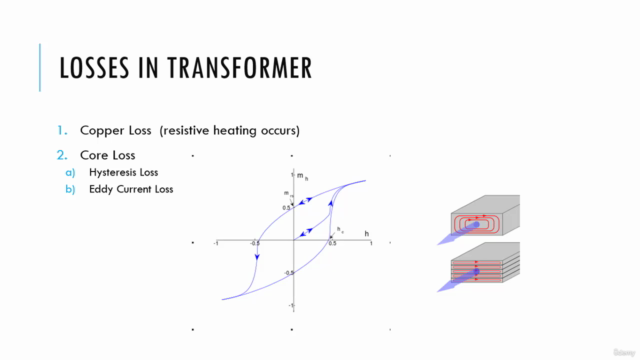

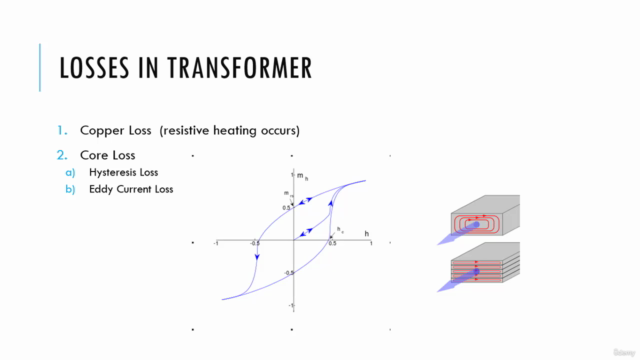

Efficiency and Losses in Transformers: Copper losses, iron losses, and overall efficiency.

-

49 and 50 Regulating Transformer and Reactors: These are used to control the flow of reactive power in the electrical system.

-

Tap Changers: Mechanisms that adjust the tap settings of transformers to optimize voltage regulation under varying load conditions.

-

Transformer Protection Systems: Including overcurrent protection, lightning arrestors, and other fault protection measures.

-

54-56 Transformer Maintenance: Regular inspections, cleaning, checking for leaks, and ensuring proper operation of protection systems.

-

Testing of Transformers: This includes open circuit tests (OC), short circuit tests (SC), impedance tests, and dielectric testing.

-

57-60 Transformer Performance and Fault Analysis: Analyzing transformer behavior under different conditions, including load testing and fault ride-through capabilities.

-

61-63 Environmental Considerations for Transformers: Proper siting to prevent damage from environmental factors like floods or storms.

-

64-66 Safety Standards for Transformers: Compliance with IEC, ANSI, and other safety standards.

-

67-69 Transformer Lifecycle Management: From manufacturing to decommissioning, including upgrades and repurposing.

-

Troubleshooting Transformers: Identifying issues such as overheating, oil breakdown, winding faults, or insulation breakdown.

-

70-72 Transformer End of Life Criteria: Determining when a transformer needs to be replaced based on performance, age, and condition.

-

73-74 Transformer Oil Management: Proper handling, disposal, and reconditioning of transformer oils.

-

75-76 Transformer Cooling Methods: Natural or forced air cooling, and liquid (oil or water) immersion cooling.

-

77-78 Insulating Materials for Transformers: Types of insulation oil, solid insulation materials, and their characteristics.

-

79-81 Transformer Core and Coil Design: Optimizing core size and coil winding to meet specific performance requirements.

-

82 Transformer Manufacturing Processes: From raw material procurement to final assembly and quality control.

-

83-84 Transformer Transportation and Installation: Ensuring the transformer arrives undamaged and is properly installed in the electrical system.

-

85-91 Transformer Testing and Commissioning: Ensuring the transformer meets all specifications before being put into service.

Each of these topics requires a deep understanding of both the theoretical aspects of transformer design and operation, as well as practical experience in installation, maintenance, and troubleshooting. The list you've provided is a solid foundation for anyone looking to gain expertise in transformer technology.

Course Gallery

Loading charts...