Injection Plastic Molding

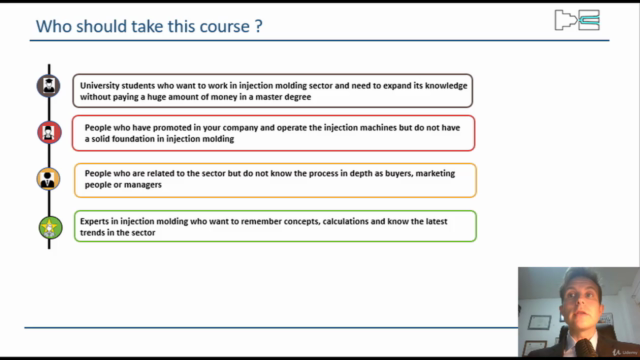

Why take this course?

🚀 Master the Art of Injection Plastic Molding with Our Comprehensive Online Course! 🎓

Why You'll Love This Course:

-

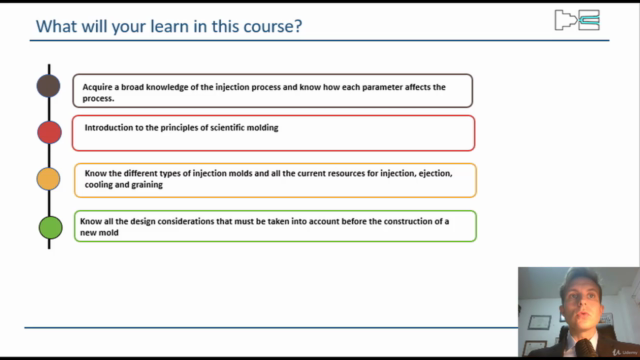

Industry Insight: Whether you're new to the field or a seasoned pro looking to refresh and expand your knowledge, this course dives deep into the scientific molding process and smart design for injection tools. 🧪✨

-

Practical Knowledge: Learn from the ground up with detailed explanations of the injection molding process, including stages, private diagnostics (Pvt Diagrams), and defect prevention. 🔬💪

-

Scientific Approach: Explore the scientific principles behind the rheology curve, cavities balance, drop pressure, seal gates, and the importance of the process window in achieving high-quality products consistently. 📊🚀

-

Expertise at Every Level: From understanding different types of injection molds, ejection systems, cooling systems, injection systems, gates, venting, and graining, this course equips you with the knowledge to excel at every stage of production. 🎭⛫

Course Structure:

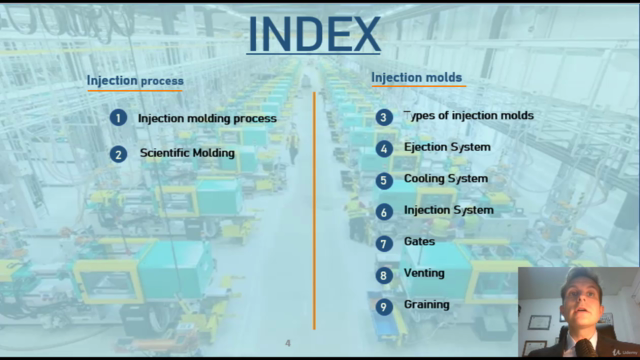

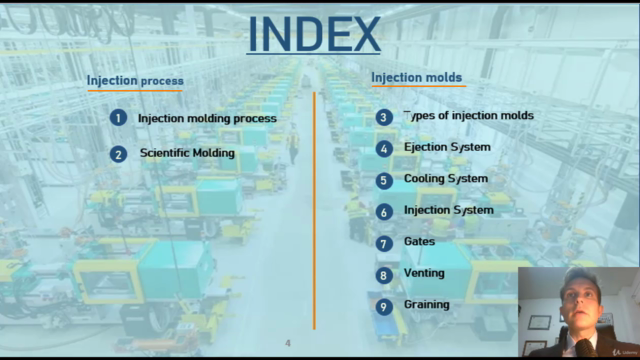

Chapter 0: Introduction

- Get acquainted with the course and its significance in the modern manufacturing landscape.

Chapter 1: Injection Molding Process

- Introduction: Dive into the world of injection molding.

- Injection cycle stages: Understand the critical phases of the process.

- Pvt Diagrams: Learn how to analyze and interpret these crucial diagrams.

- Influence of injection parameters: Discover how various factors affect your outcome.

- Calculation in injection process: Gain proficiency in essential calculations for optimal molding.

- Defects in injection molding: Identify common defects and their causes.

Chapter 2: Scientific Molding

- Rheology curve: Decode the rheology curve to enhance mold filling and packing.

- Cavities balance: Achieve balanced cavities for optimal production.

- Drop pressure: Master the science behind the perfect drop pressure.

- Seal gate: Learn about the importance of a well-designed seal gate.

- Process window: Understand the optimal range of processing conditions.

Chapter 3: Types of Injection Molds

- Introduction: Get familiar with various types of injection molds.

- Classification by feeding system: Learn how the feeding system influences mold design.

- Classification by number of plates in cavity/cores: Explore different configurations and their implications.

- Classification by number of cavities: Discover the benefits and challenges of multi-cavity molds.

- Special tools: Delve into specialized tools and their applications.

Chapter 4: Ejection System

- Introduction: Understand the role of the ejection system in molding.

- Ejection system components: Learn about pin, sleeve, and blade ejectors.

- Undercuts: Master sliders, lifters, and hydraulic movements for complex designs.

- Design of slider: Learn design principles, calculations, and recommendations.

- Design of lifters: Gain insights into lifter design, calculations, and best practices.

- Design of hydraulics: Understand the components, calculations, and recommendations for hydraulic ejection systems.

- Double ejection systems: Explore advanced ejection techniques for intricate parts.

- Cavity ejection system: Learn how to design an effective cavity ejection system.

- How is acted the ejection system: Discover the mechanics of the ejection process.

Chapter 5: Cooling System

- Introduction: Understand the importance of a well-designed cooling system.

- Calculations: Master calculations for cooling time, heat transfer, and flow in channels.

- Lay-outs: Learn about various cooling channel designs.

- Components in cooling channel: Explore different materials used in cooling systems.

- Temperatur control unit (TCU): Learn how to maintain consistent part temperatures.

Chapter 6: Injection System

- Injection system components: Delve into the intricacies of injection units and their role in molding.

- Advanced injection techniques: Learn state-of-the-art injection methods for optimal material usage.

Chapter 7: Gates

- Introduction: Understand the significance of gates in injection molding.

- Types of gates: Explore different gate designs and their applications.

Chapter 8: Venting

- Defects and locations for venting: Identify common venting issues and how to address them.

- Venting design: Learn how to design vents to prevent defects and improve part quality.

Chapter 9: Graining

- Introduction: Discover the techniques used to create grain patterns in molded parts.

- Chemical graining: Understand the process and its applications.

- Laser graining: Learn about the latest laser graining technologies.

Join us on this journey to master the art of injection plastic molding! Sign up now and transform your expertise with our comprehensive online course. 🌟🔥

Don't miss out on this opportunity to elevate your understanding and application of injection molding techniques. Enroll today and take your career to new heights! 🛠️🎯🚀

Course Gallery

Loading charts...