Introduction to Solidworks Mold tools

Why take this course?

TDM Introduction to Solidworks Mold Tools

Unlock the World of Plastic Injection Molding with SolidWorks Training!

🚀 Course Headline: Master the Basics of Plastic Injection Molding & Mold (Core & Cavity) Generation & Design using SolidWorks.

Course Description:

Dive into the intricacies of plastic injection molding with our comprehensive online course, specifically designed for learners and professionals aiming to excel in product design and manufacturing. Introduction to Solidworks Mold Tools is your gateway to understanding the critical aspects of mold design within SOLIDWORKS, a leading software in the industry for 3D product design and engineering.

🎓 Why This Course?

- Industry-Relevant Skills: Gain expertise in designing molds for mass production, essential for various industries including consumer goods, automotive, electronics, and aerospace.

- Practical Application: Learn by doing with hands-on experience using the SOLIDWORKS 2018 software and its specialized mold tools.

- Stand Out in Your Field: Enhance your resume and set yourself apart from competitors by mastering advanced SolidWorks functionalities.

Course Highlights:

- Understanding Mold Components: Familiarize yourself with core and cavity generation, parting lines, shut-off surfaces, and tooling splits.

- Real-World Applications: Learn how to apply these concepts in actual mold design for effective plastic injection or casting processes.

- Innovative Techniques: Explore the latest tools and techniques that SOLIDWORKS offers for efficient and precise mold design.

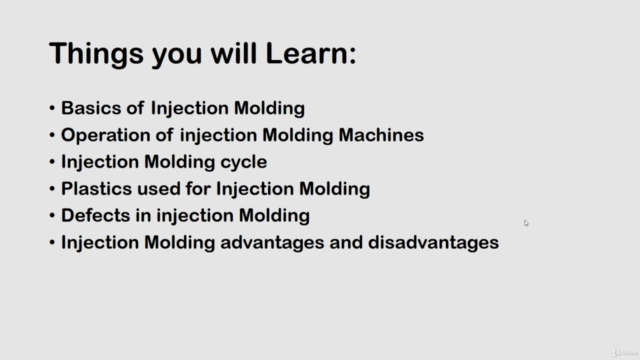

What You'll Learn:

- Mold Design Fundamentals: Get to grips with the basics of mold design, including the significance of mold lines, draft angles, and material flow.

- Feature Generation: Discover how to generate intricate features like gates, cooling lines, and ejector systems within SolidWorks.

- Mold Assembly: Learn to assemble your core & cavity setup into a complete mold assembly ready for manufacturing.

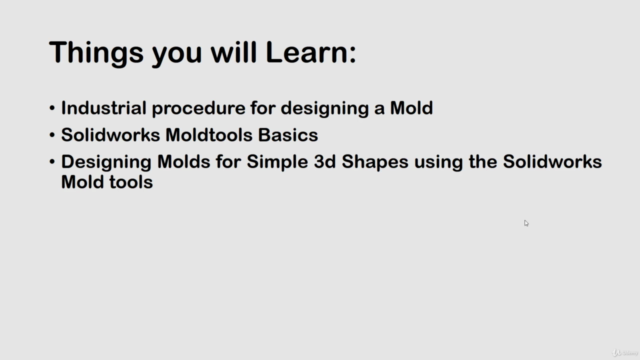

Course Structure:

- Introduction to Mold Design in SolidWorks: An overview of the mold design module and its importance in plastic injection molding.

- Core and Cavity Creation: Step-by-step guidance on generating cores and cavities, with a focus on accuracy and efficiency.

- Designing for Manufacturability: Best practices for designing molds that are easy to manufacture while maintaining design integrity.

- Advanced Mold Features: In-depth exploration of advanced features like gates, cooling lines, and ejector systems, and how they impact the quality of the final product.

- Finalizing the Mold Design: Techniques for reviewing, optimizing, and finalizing your mold design for production.

Who Should Take This Course?

- Engineers and designers in industries that use injection molding or casting.

- SolidWorks users looking to expand their skill set.

- Learners interested in the process of transforming product designs into real, manufacturable parts.

Ready to elevate your design skills and become a master of mold design in SolidWorks? 🛠️✨ Enroll now and embark on your journey towards becoming an industry expert in plastic injection molding with SolidWorks Mold Tools!

By the end of this course, you'll have a solid understanding of how to create and design molds for injection molding using SolidWorks, enabling you to contribute to the manufacturing process with confidence. Sign up today and take your first step towards becoming a proficient SolidWorks professional in the field of plastic injection molding! 🚀💫

What's Included?

- Expert-led instructional videos and live sessions.

- Interactive exercises to apply what you learn.

- Access to SOLIDWORKS 2018 software for coursework.

- A community of peers and professionals for networking and support.

- Course materials and resources for further learning.

Transform your career with Introduction to Solidworks Mold Tools – your new gateway to the world of injection molding design! 🌟

Course Gallery

Loading charts...