Introduction to FMEA (Failure Mode & Effects Analysis)

Why take this course?

**🎓 Introduction to FMEA (Failure Mode & Effects Analysis) **🎉 Master the Art of Risk Mitigation with Our Comprehensive Online Course

Course Overview: In the complex and ever-evolving world of quality assurance, one tool stands out for its reliability and effectiveness across various industries. We're talking about the Failure Mode and Effects Analysis (FMEA), a critical technique for identifying potential risks and mitigating their impact on products and processes. Whether you're an engineer, a project manager, or part of a quality control team, this course will equip you with the knowledge and skills to implement FMEA effectively in your work.

Why Take This Course? 🚀

- Comprehensive Learning: Dive deep into the three common types of FMEAs: System, Design, and Process.

- Industry-Ready Skills: Perfect for academic curricula and real-world industry applications.

- Risk Assessment Mastery: Understand the basics of FMEA and how to assess risks with confidence.

- Best Practice Approach: Learn from the most common errors and apply best practices to your FMEA process.

- Safety and Reliability Focus: Ensure safe and reliable products and processes, enhancing customer satisfaction and loyalty.

- Practical Application: Real-world examples and templates to apply what you learn immediately.

- Expert Guidance: Benefit from an instructor with extensive knowledge in FMEA methodologies.

🔹 Course Highlights:

- FMEA Fundamentals: Gain a solid understanding of what FMEA is and its importance in quality management.

- Risk Assessment Framework: Learn how to evaluate and prioritize risks effectively.

- Real-World Applications: See how FMEA can be applied across various industries, from automotive to aerospace.

- FMEA Worksheet Tools: Get your hands on practical worksheets and examples to guide you through the process.

- Best Practices for Success: Discover strategies that will make your FMEA process more effective and efficient.

- Benefits of a Thorough FMEA: Understand how a well-executed FMEA can lead to cost savings, reduced product development time, and improved safety standards.

- FMEA vs Testing: Learn the differences between FMEA and traditional testing methods to make informed decisions in your process.

- Interactive Learning: Engage with an end-of-course exercise featuring a Q&A session for immediate feedback.

- Continuous Improvement: Explore how FMEA contributes to the continuous improvement of products and processes.

📚 Course Content Breakdown:

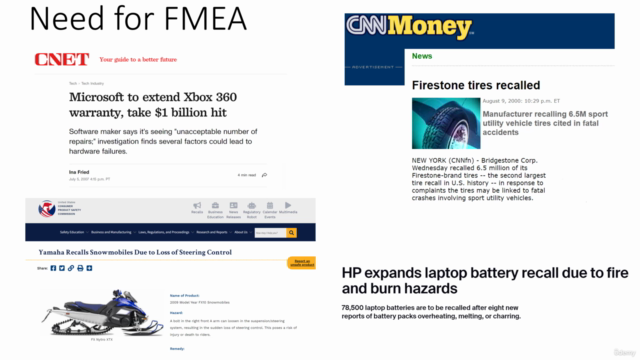

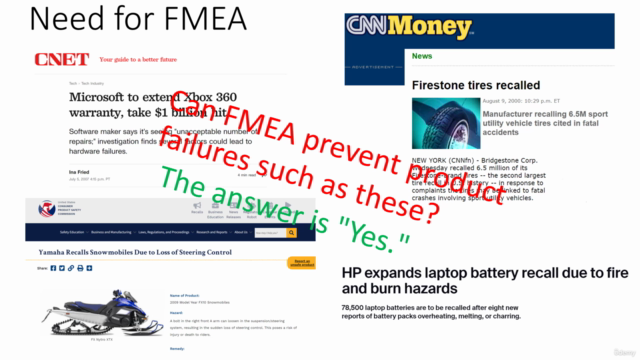

- Need for FMEA - Understanding the critical role of FMEA in modern manufacturing and design.

- What is FMEA? - Definition, objectives, and how it differs from other analysis tools.

- What is FMEA used for? - Exploring the various applications of FMEA within different industries.

- Types of FMEA - An overview of System, Design, and Process FMEAs.

- FMEA Worksheet - Template - Step-by-step guide to creating your own FMEA document.

- FMEA Worksheet - Example - Review a sample FMEA to see best practices in action.

- FMEA Best Practices - Insights into the most effective strategies for conducting an FMEA.

- Benefits of Good FMEA - Learn why a well-executed FMEA is crucial for your product's success.

- FMEA vs Testing - Comparing and contrasting FMEA with traditional testing methods.

- Exercise – Q&A - A chance to test your knowledge with 10 multiple-choice questions.

- Summary - Recap the key takeaways and how to apply them in your work environment.

Ready to master FMEA? Enroll now and transform your approach to quality management! 🎓✨

Course Gallery

Loading charts...