CNC Programming l Write G-Code and M-Code

Why take this course?

🌟 Master CNC Programming with Expert Swaylen!

🚀 Course Title: Unleash Your Potential with CNC Machining - Write G-Code and M-Code for Lathe Operations using eCAM Software

🔥 Headline: Elevate Your CNC Skills: Precision Lathe Programming with G-Code & M-Code in eCAM

Course Description:

Dive into the world of Computer Numerical Control (CNC) and become a master in CNC programming! This comprehensive course is designed to take you from a beginner to an expert in writing effective G-Code and M-Code for CNC lathe operations, utilizing state-of-the-art eCAM software.

Why Choose This Course?

- Industry-Standard Software: Learn the ins and outs of eCAM software, which is widely used in various industries for efficient and precise CNC machining.

- Hands-On Experience: Get practical experience by writing actual G-Code and M-Code that can be applied directly to CNC lathe operations.

- Comprehensive Instruction: From the basics of CNC machines to advanced programming techniques, this course covers everything you need to know.

- Axis Information Mastery: Understand how to use the axis information of a machine effectively to execute complex tasks with precision and control.

Course Structure:

-

Introduction to CNC Machining:

- What is CNC?

- The evolution of CNC technology.

- Key components of a CNC machine.

-

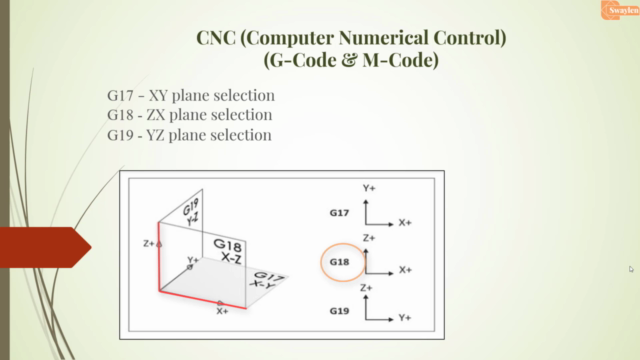

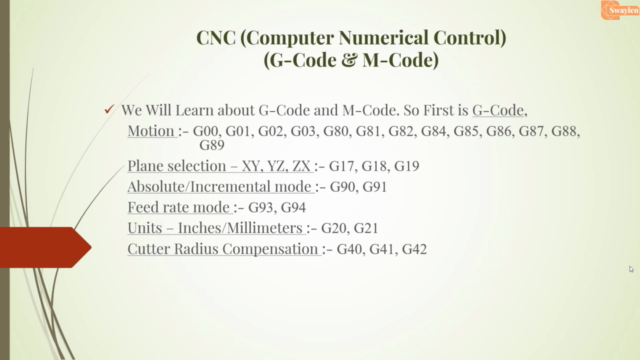

Understanding G-Code & M-Code:

- The role of G-Code and M-Code in CNC programming.

- Command structure and syntax.

- How to interpret and apply different types of commands for various machining tasks.

-

CNC Machine Interface & Coordinate Systems:

- Learning the interface of eCAM software.

- Understanding Cartesian, Inverse Time, and Dynamic coordinate systems.

- Setting up work coordinates and programming for optimal performance.

-

Writing G-Code for Lathe Operations:

- Crafting G-Code for basic lathe operations like turning, facing, threading, etc.

- Utilizing M-Codes to control the spindle, coolant, and other functions of the CNC lathe.

- Strategies for optimizing toolpaths and material removal.

-

Practical Application & Simulation:

- Hands-on exercises to write and simulate real G-Code and M-Code programs.

- Tips and tricks from industry veterans.

- Real-world case studies and problem-solving scenarios.

-

Final Project:

- Apply all the skills learned to create a comprehensive CNC program for a lathe operation.

- Debug and refine your code for efficiency and accuracy.

Who Should Take This Course?

- Aspiring CNC Programmers & Hobbyists.

- Engineers & Technicians in Manufacturing, Aerospace, Automotive, or any industry utilizing CNC machinery.

- Students of Mechanical Engineering, Mechatronics, and related fields interested in CNC programming.

- Anyone looking to upskill and enhance their career opportunities in the field of advanced manufacturing.

Join us now and transform your understanding of CNC programming with expert guidance from Swaylen, a renowned CAD/CAM/CAE expert. 🛠️💻✨

Enroll today and take your first step towards becoming a CNC Programming pro! 🚀🔥

Course Gallery

Loading charts...