Catia V5 Machining Essential Training

Why take this course?

🎓 Unlock the Full Potential of Catia V5 Machining with Our Essential Training Course!

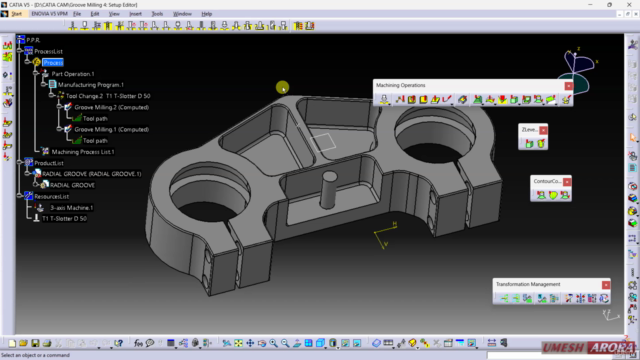

🚀 Course Overview:

Dive into the world of advanced machining with our comprehensive Catia V5 Machining Essential Training course. This platform is designed for learners looking to master the intricacies of CATIA V5's 3-Axis and 5-Axis machining capabilities. Whether you're a beginner or an experienced user aiming to refine your skills, this course will guide you through the powerful tools and features available in CATIA V5 to optimize your machining processes.

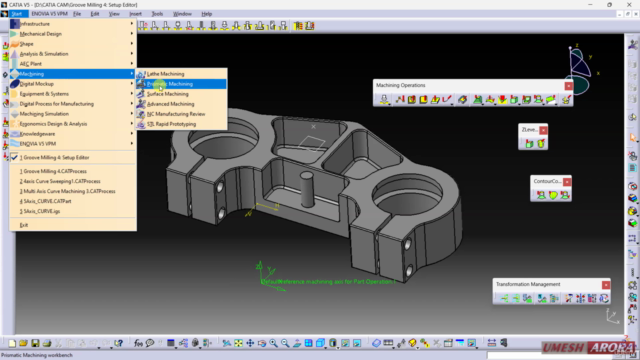

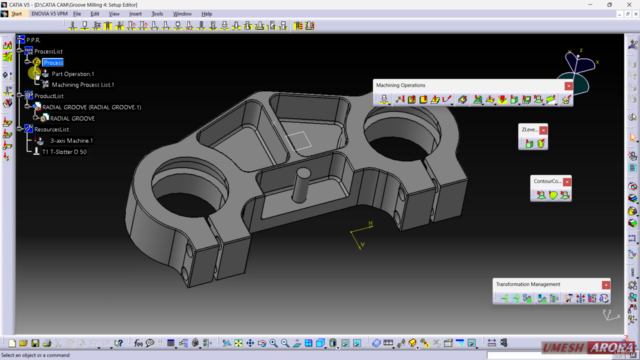

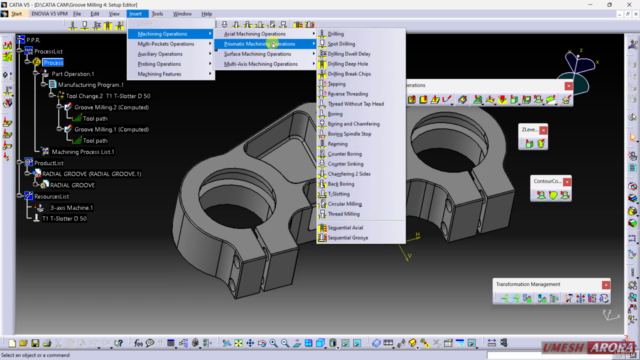

🔧 Mastering CATIA - Prismatic Machining:

- Automated Feature Recognition: Learn how Catia V5 automatically generates all prismatic geometrical machining features for milling and drilling, ensuring a streamlined workflow for your manufacturing needs.

- Automatic creation of prismatic features

- Seamless integration into the CATIA Prismatic Machining product

- Execution of accurate 2.5-axis milling and drilling operations

- Quick and efficient tool path verification with various display options for precision machining.

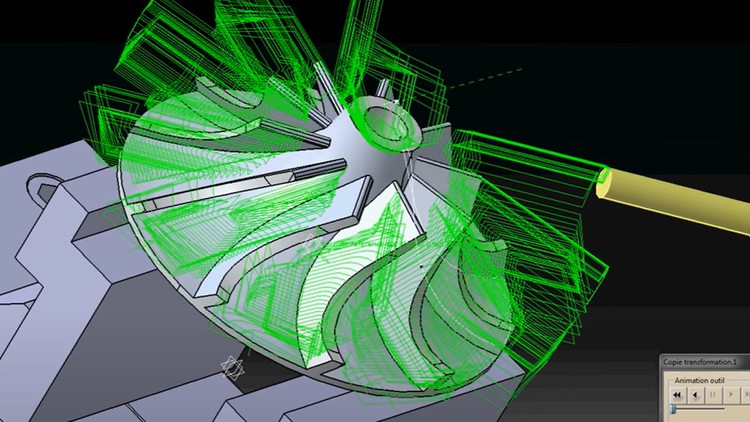

🌟 Exploring 3-Axis Surface Machining:

- Efficient NC Programming: Easily define NC programs for machining complex 3D parts using advanced 3-axis surface machining operations within Catia V5.

- Define tool paths for 3-axis milling and drilling

- Perform accurate material removal simulations in both wireframe and 3D views for optimal verification.

🔮 Advanced 4-Axis & 5-Axis Machining:

- Precision & Complexity: Discover the capabilities of 4-axis and 5-axis roughing and finishing machining operations in Catia V5.

- Define NC programs for both roughing and finishing operations

- Utilize all available options for 4-axis and 5-axis milling and drilling to enhance your tool path precision.

- Experience advanced material removal simulations with clear visualization in both wireframe and 3D views.

🔍 NC Manufacturing Verification:

- In-Depth Analysis: Learn to validate machining processes with CATIA V5's simulation and verification tools, ensuring the accuracy of your machined parts.

- Perform advanced verification for 3-axis, 4-axis, and 5-axis positioning and machining.

- Visualize potential collisions between the tool, tool holder, or shank and the part or fixtures to avoid damage.

- Generate NC programs tailored for manufacturing operations and select appropriate post processors for your setup.

🎓 Why You Should Enroll:

- Skill Enhancement: Elevate your CATIA V5 skills by understanding the full scope of machining capabilities.

- Industry Applicability: Apply your newfound knowledge to real-world manufacturing scenarios across various industries.

- Career Advancement: Strengthen your CV and open up new career opportunities in engineering, design, and manufacturing sectors.

- Practical Experience: Get hands-on experience with CATIA V5's advanced machining features through structured learning modules and exercises.

📅 Key Takeaways:

By the end of this course, you will have a thorough understanding of:

- How to efficiently set up prismatic and surface machining operations in Catia V5.

- The capabilities and limitations of 4-axis and 5-axis machining with CATIA V5.

- How to simulate and verify your machining processes for accuracy and efficiency.

- Best practices for generating NC programs and setting up post processors.

🤝 Join Our Community of Learners and Professionals:

Embark on a journey of learning with peers who share your passion for CATIA V5 and advanced manufacturing. Engage with our community, participate in discussions, and exchange knowledge to further enhance your expertise.

Enroll now and take the first step towards mastering Catia V5 Machining with our Essential Training course! 🌟

Course Gallery

Loading charts...