Advanced Welding Metallurgy for Certified Welding Inspectors

Why take this course?

🌟 Master AWS Certified Welding Inspector (CWI) Metallurgy with Dr. Faizuddin Syed 🌟

Course Title: AWS - CWI-Advanced Welding Metallurgy

Module-3, Part 1/Part 2/Part 3/Part 4/Part 5/Part 6/Part 7

Course Headline: Welding Metallurgy and Weldability of Steel Alloys

Course Description:

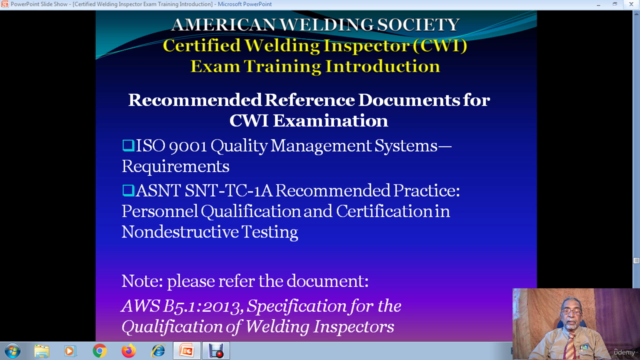

The Certified Welding Inspector (CWI) exam is a comprehensive test that assesses the candidate's expertise in various aspects of welding inspection. It is divided into three parts:

- Part A (Written Examination): Tests your knowledge of welding, cutting, bending, and related processes, including theory, practices, symbols, terminology, calculations, and safety requirements.

- Part B (Practical Examination): Evaluates your ability to inspect welds in the field and determine weld quality according to code requirements.

- Part C (Oral Examination): Assesses your understanding of the written and practical examinations, including knowledge of the AWS codes and standards.

What You'll Learn:

Understanding Metallurgical Changes During Welding:

- Liquid Metal Solidification Modes

- Centre line weld solidification cracks

- Microstructure of the welded metal

- Solidification of Weld Metal

- Dendrite Growth, time, and Primary spacing

- Gas-Metal Reactions during Welding

- Welding of Ferrous Metals

- Welding of Nonferrous Metals

- Reactions of Liquid Metals

- Hot Crack or Solidification Cracking

- Reactions of Solid State

- Delayed Cracking

- Cold Cracking

- Hydrogen Induced Cracking

Weld Strengthening Mechanisms:

- Solidification of Grain Structure

- Solid Solution Strengthening

- Effect of temperature on Tensile strength

- Precipitation Hardening

- Heat affected Zone

- Solid Solution Strengthened Alloys

- Strain Hardened Base Metals

- Re-crystallization of Cold Worked Grains in Heat-Affected Zone

- Precipitation of Hardened Alloys

- Transformation Of Hardening Alloys

Base Metal Weldability and Commercial Alloys:

- Plain Carbon Steels- Low Alloy Steels

- High Alloy Steels

- Types of Stainless Steels

- Other High Alloy Steels

- Aluminum Alloys

- Magnesium Alloys

- Copper Alloys

- Nickel Base Alloys

- Cobalt Alloys

- Refractory and Reactive Metals

- Titanium Alloys

- Zirconium

- Hafnium

- Tantalum

- Columbium

- Molybdenum

- Tungsten Alloys

- Beryllium

NDT Fundamentals:

- VT (Visual Testing)

- MT (Magnetic Particle Testing)

- UT (Ultrasonic Testing)

- PT (Penetrant Testing)

- RT (Radiographic Testing)

- LT (Leak Testing)

Quality Procedures and Compliance:

- Knowledge of quality procedures and Quality audits/surveillance

- Fundamentals of welding metallurgy

- Welding symbols and engineering drawings

- Base material and filler metal compatibility

- Certification of documented results and compliance

- Procedure qualification records compliance

- NDE procedures compliance

- Applicable safety requirements in the workplace as per the International Standards

Why Take This Course?

✅ Expert Instructor: Learn from Dr. Faizuddin Syed, an expert with years of experience in the field.

✅ Comprehensive Content: Cover all aspects of the CWI exam and gain a deep understanding of welding metallurgy.

✅ Practical Knowledge: Understand the real-world applications of welding inspection and metallurgy.

✅ Prepare for AWS Certification: Meet the requirements for the AWS Certified Welding Inspector (CWI) certification.

✅ Enhance Your Career: Position yourself as a leading expert in welding metallurgy and inspection, opening up new career opportunities.

Join this enlightening course to elevate your expertise in welding metallurgy and become an AWS-certified welding inspector. Enroll now and take the first step towards a prosperous career in welding technology.

Course Gallery

Loading charts...