Flanges in Piping Systems: Types, Ratings, and Standards

Why take this course?

🛠️ Mastering Flanges in Piping Engineering 🧐

Course Title: All about Flanges: Piping Engineering

Course Headline:

Unlock the Mysteries of Flanges with Flanges II PT Rating II ASME B16.5 II ASME B16.47 🛠️

What is a Flange?

Flanges are vital components in any piping system, serving as the connection point between different sections of pipework, equipment, and instruments. They allow for the maintenance and repair of systems without compromising structural integrity. Let's explore the various types of flanges and their functions within a piping network.

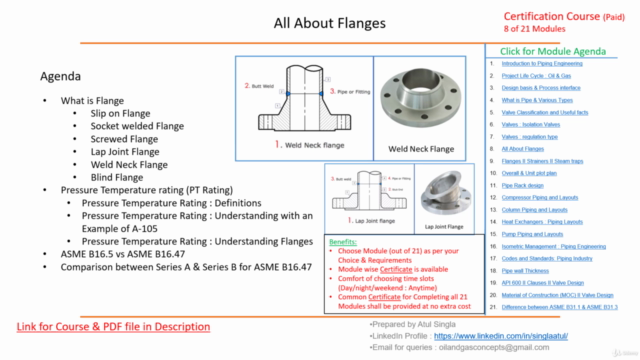

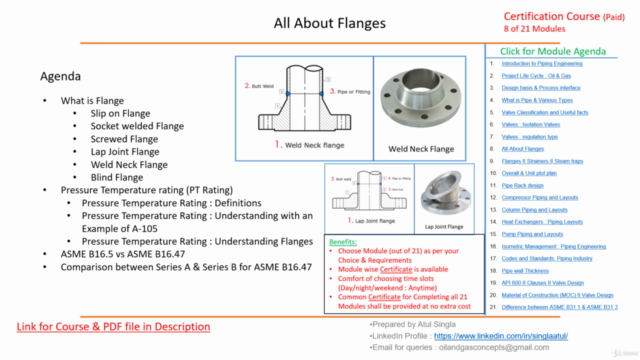

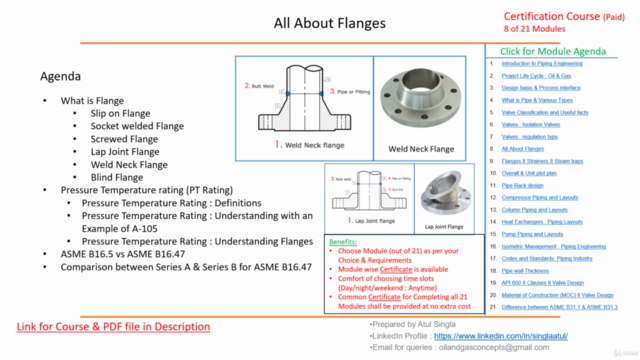

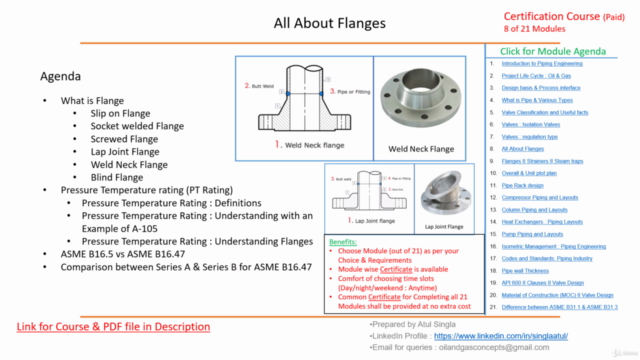

Types of Flanges:

- Slip on Flange: A versatile option where the flange is slipped over the pipe end, designed for pipes with a consistent thickness.

- Socket Welded Flange: Features a socket to receive the pipe end, which is then welded into place.

- Screwed Flange: Utilizes screws or bolts for a secure connection, suitable for smaller diameter pipes.

- Lap Joint Flange: Involves two flanges that overlap and are bolted together, providing a strong, leak-proof joint.

- Weld Neck Flange: The gasket surface is perpendicular to the axis of the pipe, making it ideal for high-pressure or high-temperature applications.

- Blind Flange: Seals the end of a pipeline and can be used in both pressure and vacuum services.

Understanding Pressure Temperature (PT) Rating:

The PT rating is crucial as it dictates the maximum allowable operating conditions for a flange. Let's demystify this with an example:

- Pressure Temperature Rating: Definitions: We'll define what PT Rating means and why it's essential for your piping systems.

- Pressure Temperature Rating: Understanding with an Example of A-105: Learn how a specific material grade, like A-105, can handle different temperatures and pressures.

- Understanding Flanges within PT Ratings: We'll guide you through how to select the correct flange based on your system's requirements.

ASME B16.5 vs ASME B16.47:

Diving deeper into the standards, we compare the two most commonly referenced American Society of Mechanical Engineers (ASME) codes for flanges:

- Comparison between Series A & Series B for ASME B16.47: Understand the differences and applications for each series.

Frequently Asked Questions:

What is a Pipe Flange? A pipe flange connects piping and components in a piping system by use of bolted connections and gaskets, providing a reliable and robust joint.

Where are pipe flanges used? Flanges are essential for connecting pumps, pipes, valves, and other equipment, making them the backbone of a functional and accessible piping system.

What are the types of flange? There are eight primary types of flanges in piping: blind, lap joint, orifice, reducing, slip-on, socket-weld, threaded, and weld neck. Each serves a different purpose depending on the application.

What is the function of flange? Flanges facilitate the joining of pipes with other pipes, valves, fittings, and specialty items, ensuring a secure connection while allowing for maintenance access.

Why are pipe flanges important? Pipe flanges are crucial for maintaining system integrity, enabling ease of maintenance, inspection, and repair without the need to dismantle large sections of piping.

How many types of flanges in piping? Piping flanges come in eight different designs, each tailored to specific applications and pressures.

What is a steel flange? A steel flange is a forged or cast component that serves to connect or reinforce pipelines, columns, or beams, providing structural support and ensuring the longevity of the system.

The Raised Face (Raised Face - RF) Flange: This is the most common type of flange used in process plant applications. It features a raised gasket surface that makes it easy to identify and use.

By the end of this course, you'll have a comprehensive understanding of flanges, their types, standards, and how to apply them effectively in various piping scenarios. Get ready to join the ranks of professionals who master the art of flange selection and application with All about Flanges: Piping Engineering. 🏭✨

Course Gallery

Loading charts...